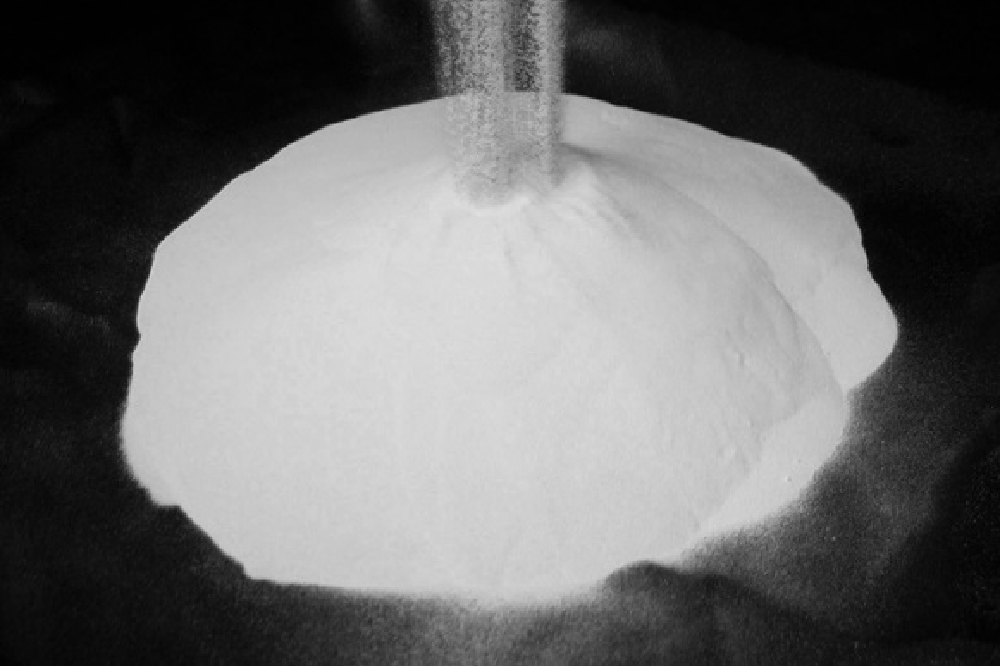

Calcia Stabilized Zirconia

In the case of pure zirconia, a phase transition occurs at 1000℃ from monoclinic (a box-shaped crystal that combines all rectangles like a tissue box) to a tetragonal crystal (a box-shaped crystal that combines rectangles and squares). For this reason, CaO (calcium oxide) is generally mixed (these are called stabilizers). Once these stabilizers are dissolved in sufficient quantities in the crystals, the zirconia will not undergo transition until it becomes liquid. This is called “stabilization”, and the product stabilized with CaO is called CaO-stabilized zirconia.

Use

● High-temperature firing furnace internal materials (furnace core tubes, furnace protection materials, construction materials)

●Materials for refractory metal heat treatment (nickel, tungsten, tungsten carbide, tantalum)

●Furnace materials for quartz melting

Characteristic examples

| Product Name | Calcia Stabilized Zirconia | |

|---|---|---|

| Chemical composition(wt%) | ZrO2(+HfO2) | 94-97 |

| SiO2 | ≤0.45 | |

| Fe₂O₃ | ≤0.10 | |

| TiO2 | ≤0.30 | |

| Al₂O₃ | ≤0.50 | |

| CaO | 3.6-4.2 | |

| Specification | Particle Distribution | ||||||

|---|---|---|---|---|---|---|---|

| +380μm~ | +212μm~ | +150μm~ | +75μm~ | +62μm~ | +53μm~ | +45μm | |

| CSZ40 | ≤5 | ≥70 | |||||

| CSZ100 | ≤5 | ≥90 | |||||

| CSZ200 | ≤5 | ≤10 | ≤15 | ≤30 | |||

| CSZ325 | 0(D50=9~13μm) | ||||||